Bob Martin Co. provides 100% alloy identification to achieve highest quality possible, using Acromag Metal Tester and Niton Metal Analyzer.

Positive Material Identification (PMI) refers to the identification and analysis of various metal alloys based on their chemical composition in nondestructive testing (NDT). Because specifications for wiring used in industry are increasingly more specific, the need for PMI testing has been steadily increasing for the past several years.

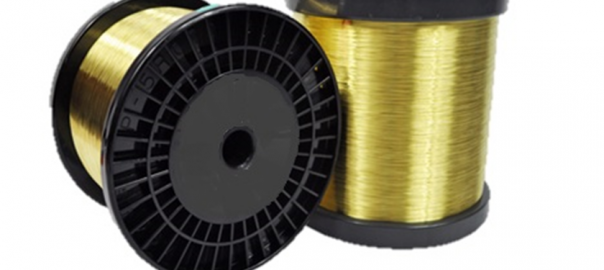

A wider variety of alloys that are indistinguishable to the eye are being used in individual plants. When facility staff replace wiring, they must be able to guarantee that the new wiring matches engineering specifications.

PMI is a field-testing method made possible by the portability of most PMI analyzers. These instruments also can be used in the laboratory. Source: Oxford Instruments

Positive Material Identification (PMI) refers to the identification and analysis of various metal alloys based on their chemical composition in nondestructive testing (NDT). Measurement results are shown in the form of elemental concentration in percentage or by specific alloy name such as SS316L or Inconel 625. PMI is a field-testing method made possible by the portability of most PMI analyzers. These instruments also can be used in the laboratory.

Global sourcing is another factor driving the need for PMI. Currently, metal buyers and suppliers are operating globally, and buyers need to verify the quality of the product they are receiving.

Contact Us for more information about alloy identification.