At Bob Martin Company, we pride ourselves on providing a comprehensive range of wire services tailored to meet the diverse needs of our clients. From wire drawing and straightening to cutting and alloy identification, our services are designed to ensure precision, quality, and reliability. Let’s dive into the specific benefits and details of each service we offer.

Wire Drawing

Wire drawing is a fundamental process in the production of wire products. It involves pulling a wire through a series of dies to reduce its diameter and increase its length. Here’s why our wire drawing service stands out:

- Precision and Consistency: Our advanced wire drawing equipment ensures that every wire meets exact specifications, providing uniformity and precision across all products.

- Versatility: We can draw wires from various materials, including copper, aluminum, and steel, catering to a wide range of industrial applications.

- Enhanced Strength: The drawing process enhances the mechanical properties of the wire, such as tensile strength and hardness, making it suitable for demanding applications.

Wire Straightening and Cutting

For many applications, wires need to be perfectly straight and cut to specific lengths. Our wire straightening and cutting service is designed to meet these requirements with high accuracy and efficiency.

- Accuracy: Using state-of-the-art machinery, we ensure that each wire is straightened to precise standards and cut to the exact length required by our clients.

- Efficiency: Our automated processes allow for rapid production without compromising on quality, enabling us to handle large orders with quick turnaround times.

- Customization: We can accommodate a variety of wire sizes and materials, providing bespoke solutions tailored to the specific needs of our clients.

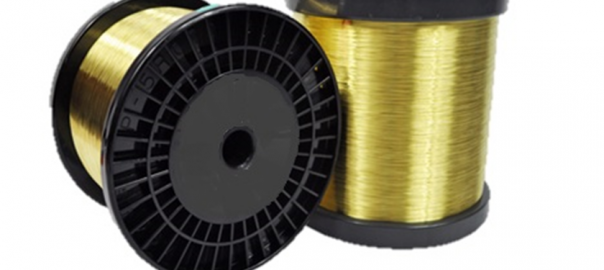

Spooled Wire

Spooled wire is essential for many industries, providing a convenient and efficient way to handle and transport wire products. Our spooled wire services offer:

- Convenience: Wires are neatly wound on spools, making them easy to store, transport, and use without the hassle of tangling.

- Customization: We offer spooled wire in various lengths, diameters, and materials, ensuring that our clients get exactly what they need for their specific applications.

- Quality Assurance: Each spool is carefully inspected to ensure that the wire meets our stringent quality standards, providing our clients with reliable and consistent products.

Alloy Identification

Quality is at the heart of everything we do, and alloy identification is a critical component of our quality assurance process. We use cutting-edge technology to ensure that we deliver top-notch quality wire products.

- Acromag Metal Tester: This advanced tester allows us to quickly and accurately identify the composition of metals, ensuring that the materials used in our wires meet the required specifications.

- Niton Metal Analyzer: Our Niton Metal Analyzer provides detailed alloy identification, giving us precise information about the metal composition and ensuring the highest standards of quality.

- Quality Assurance: By thoroughly analyzing the alloys used in our wire products, we can guarantee that our clients receive products that meet their exact requirements and industry standards.

Why Choose Bob Martin Company?

Choosing Bob Martin Company for your wire needs means opting for precision, quality, and reliability. Our comprehensive range of wire services, coupled with our commitment to using the latest technology and maintaining stringent quality standards, ensures that we can meet the diverse needs of our clients across various industries.

Whether you need wire drawing, straightening and cutting, spooled wire, or alloy identification, Bob Martin Company has the expertise and equipment to deliver exceptional results. Contact us today to learn more about our services and how we can help you achieve your project goals with our top-notch wire solutions.