Our Wire Spooling Services: Layer Level Winding and Random Winding for Every Customer Need

At Bob Martin Co., wire spooling is more than just a process – it’s a precision service tailored to meet the unique needs of every customer. Whether you’re in need of layer level winding for organized and consistent spooling or random winding for quick, high-volume applications, we have the expertise and equipment to deliver exactly what your project requires.

What is Wire Spooling?

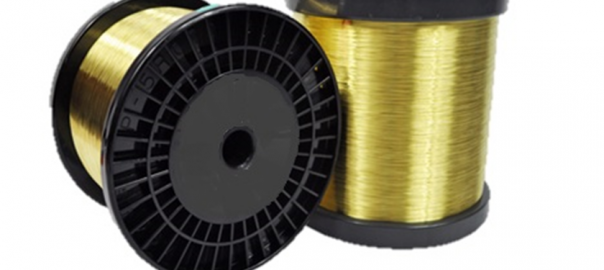

Wire spooling refers to the process of winding wire onto spools or reels for safe storage, easy transportation, and efficient use. Spooling ensures that wire remains tangle-free, accessible, and ready for deployment in manufacturing, construction, and other industries.

At Bob Martin Co., we offer two primary spooling methods:

1. Layer Level Winding

Layer level winding involves tightly winding the wire in a uniform, even pattern. Each layer of wire is neatly stacked, minimizing gaps and preventing tangling. This type of winding is essential for:

- Precision wiring applications

- Electrical components

- Aerospace and medical industries

The uniform nature of layer winding ensures smooth unwinding during use, reducing downtime and improving efficiency.

2. Random Winding

Random winding is a more flexible and less structured spooling technique. It allows wire to be wound quickly, without a strict pattern, making it ideal for:

- High-volume production

- Temporary storage

- Applications where wire will be cut and used in smaller segments

Random winding offers a fast and cost-effective solution when perfect alignment isn’t necessary.

Custom Spooling Solutions for Every Industry

We work with a wide variety of spool types to accommodate specific customer requirements, whether you’re dealing with small-scale electronics or industrial applications. Our wire spooling services extend across multiple industries, including automotive, medical, and telecommunications.

Need a specific spool size or material? No problem! We offer customizable options to ensure that the spooled wire meets your exact specifications, ensuring safe handling and seamless integration into your workflow.

Why Choose Bob Martin Co. for Wire Spooling?

Choosing the right partner for wire spooling makes all the difference. Here’s why companies trust Bob Martin Co.:

- Precision and Quality Control: Every spool is inspected for quality and consistency.

- Flexibility: We handle both small and large production runs, ensuring fast turnaround times.

- Industry Expertise: With years of experience, we understand the spooling needs across industries.

- Customer Focus: Customization is at the core of what we do – if you have specific requirements, we’ll make it happen.

Get Your Wire Spooling Needs Met Today

At Bob Martin Co., we’re committed to delivering the highest quality wire spooling services to meet your production needs. Whether you require layer level winding for precision or random winding for speed, our team is ready to assist. Visit our wire services page to learn more about how we can help streamline your operations.

For more information, contact us today and discover how our spooling solutions can enhance your manufacturing processes.