In the world of manufacturing, the choice of materials can significantly influence the efficiency and success of the final product. One standout material in the aircraft industry is the 2024 Aluminum Alloy Wire. Known for its robust properties and critical applications, let’s delve into what makes this alloy a preferred choice for aerospace engineering.

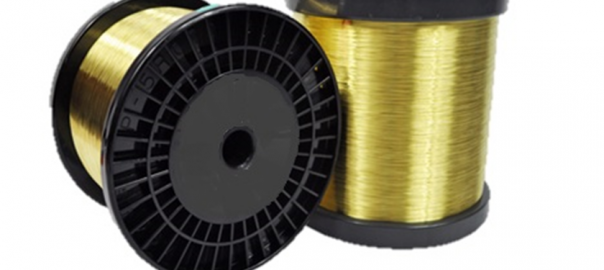

What is 2024 Aluminum Alloy Wire?

2024 Aluminum Alloy Wire is a heat treatable alloy that is renowned for its excellent strength and hardness. This type of wire is specifically designed for cold heading, a process used to form the wire into precision shapes without significant heating. Its mechanical properties make it ideal for high-stress structural parts, especially in the aerospace sector.

Key Features and Benefits

- Exceptional Strength and Durability: The primary benefit of 2024 Aluminum Alloy Wire is its high strength-to-weight ratio. This feature is critical in aerospace applications where every kilogram saved can lead to better fuel efficiency and performance.

- Heat Treatability: This alloy can be heat-treated to further enhance its mechanical properties. This treatment allows the wire to achieve superior hardness and strength, making it capable of withstanding the rigorous demands of aircraft operations.

- Suitability for Cold Heading: The cold heading capability of 2024 Aluminum Alloy Wire means that it can be molded into fasteners and other components without the need for extensive heating. This process retains the material’s structural integrity and strength.

Applications in the Aircraft Industry

The 2024 Aluminum Alloy Wire is predominantly used in the production of high-stress aircraft parts. These include components like fuselage and wing tension members, shear webs and ribs, and other structural areas that require robustness. Its ability to be formed into complex shapes also makes it invaluable in the intricate assemblies typical of modern aircraft.

Despite its strengths, 2024 Aluminum Alloy Wire does have some limitations. One notable drawback is its low corrosion resistance. In environments prone to corrosion, this alloy must be treated or coated with protective layers to prolong its life and maintain its integrity. This is a crucial consideration for aircraft operating in marine or highly corrosive environments.

The 2024 Aluminum Alloy Wire stands out in the aircraft industry for its exceptional strength, heat treatability, and suitability for cold heading, making it an essential material in the production of critical aircraft components. However, understanding its limitation in corrosion resistance is crucial for maximizing its effectiveness and longevity in aerospace applications.

At Bob Martin Company, we continue to explore and provide insights into the materials that are shaping the future of industries. Stay tuned for more in-depth discussions on innovative solutions and technologies that are driving the aerospace sector forward. Contact us for more information.